一、Summary

Triaxial compression test is a method to measure the shear strength of soil. It usually uses three to four cylindrical specimens, under different constant ambient pressure (i.e. small principal stress σ3), to apply axial pressure (i.e., principal stress difference (σ1-σ3)), and shear until failure. Then the shear strength parameters are obtained according to the Moore-Coulomb theory. According to different drainage conditions, there are three test types: unconsolidated undrained shear (UU), consolidated undrained shear (CU) and consolidated drained shear (CD).

Tt-ats1 automatic triaxial compressorIt is developed on the basis of triaxial compression test theory. It integrates mechanical, electronic, automation and sensor technology. On hardware is mainly composed of three axis load and confining pressure and back pressure controller, its supporting system software can provide the test set, system control, data acquisition and data processing functions, such as interactive performance is good, the product on the basis of the original triaxial apparatus to improve its control system, adopts the circuit design, test process without human intervention, improve the test efficiency.

二、Main features

|

Stepper motor control |

It can realize triaxial strain control test, strain rate 0.001-4mm/min, stepless variable speed |

|

Confining pressure and back pressure control |

Equipped with high precision hydraulic volume controller, hydraulic chamber capacity 250ml, pressure range 0-2mpa, external

LCD touch screen with automatic protection against excessive pressure and volume. Volume resolution

Is 0.1 mL, volume accuracy is 0.1%F.S, pressure accuracy is 0.3%F.S, pressure resolution is 1kPa.

It can be controlled by constant voltage or constant current

|

|

Backpressure saturation |

Backpressure saturation is realized by backpressure hydraulic controller |

Accurate test data |

The sensors used in the instrument are high-precision sensors, accurate and stable. Axial pressure 0-10kN, accuracy 0.3%F.s, resolution 1N; Confining pressure, back pressure, pore pressure 0-2mpa, accuracy 0.3%F.s, resolution 1kPa; Displacement 0-100mm, accuracy 0.5%F.s, resolution 0.1mm |

三、Possible tests

Consolidation drainage triaxial test (CD), consolidation undrained triaxial test (CU), unconsolidation undrained triaxial test (UU)

四、Upgrade options

Penetration test, stress path test, tensile test, elastic modulus test, etc.

五、Main technical parameters

☆ Sample size: φ 39.1x80mm

☆ Vertical pressure: 0-10kN, accuracy 0.3%F.s, resolution 1N

☆ Surrounding pressure: equipped with high precision hydraulic volume controller, hydraulic chamber capacity of 100ml, pressure range of 0-2mpa, built-in LCD touch screen, with automatic protection device to prevent excess pressure and volume. The volume resolution is 0.1mL, the volume accuracy is 0.1%F.S, and the pressure accuracy is 0.3%F.S, and the pressure resolution is 1kPa. It can be controlled by constant voltage or constant current

☆ Back pressure: equipped with high precision hydraulic volume controller, hydraulic chamber capacity of 100ml, pressure range of 0-1mpa, built-in LCD touch screen, with automatic protection device to prevent excess pressure and volume. The volume resolution is 0.1mL, the volume accuracy is 0.1%F.S, and the pressure accuracy is 0.3%F.S, and the pressure resolution is 1kPa. It can be controlled by constant voltage or constant current

☆ Pore pressure: 0-2mpa high precision pressure sensor, accuracy 0.3%F.S, resolution 1kPa

☆ Discharge water variation: measured by the back pressure hydraulic volume controller, high accuracy, good reliability, displacement ≤0-100ml, resolution 0.1ml

☆ Three axis load frame: output ≤20KN, equipped with LCD touch screen, real-time display of displacement, load, pore pressure and other parameters, computer control automatic control; Strain rate 0.001-4/min, stepless variable speed, relative error ≤3%

六、System composition configuration and options

☆ Data acquisition and digital control system

The system uses a 32-bit high-speed ARM processor and a digital circuit to control the displacement and load. Equipped with 24-bit data acquisition (A/D); Equipped with high precision proportional valve, can stably control the confining pressure; Equipped with 640x480 LCD touch screen, display the test indicators; Equipped with high-speed RJ45 network port, realize communication with computer software.

☆ High precision stepper motor loading system

Using stepper motor control loading system, high precision to achieve axial loading control; The system is an important part of the triaxial experiment,

It not only exerts axial load on samples, but also has the key function of measuring displacement and axial pressure of soil samples. The control system and precise ball screw push the loading platform to apply axial load to the pressure chamber, and the strain type triaxial test can be carried out. The static loading rate of the system (0.001~4mm/min) is composed of servo motor, driver, single-chip microcomputer control system and load sensor.

☆ High precision pressure/volume controller

Equipped with a set of 2MPa/100cc pressure/volume controller, used for confining pressure, back pressure control and displacement measurement, can achieve constant current and constant pressure two loading modes; Built-in overload and over-voltage protection device, pressure measurement accuracy is 0.3% of the full range, resolution is 1kPa, volume measurement accuracy is 0.1% of the full range, resolution is 0.1ml.

☆ Computer data acquisition and processing software

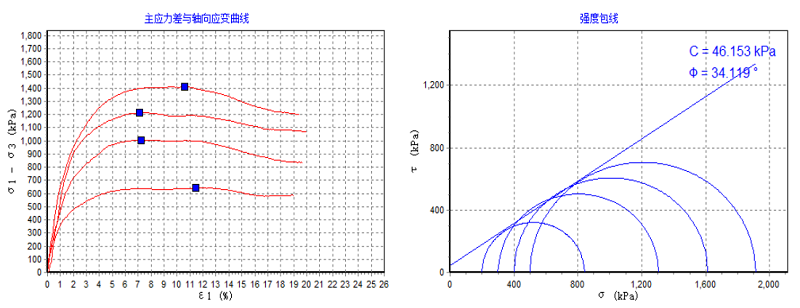

A set of control, acquisition, processing in one of the software platform, using network communication, real-time control of the test; With data acquisition function, real-time acquisition and display of data and curves in the test process; Have data processing function, draw mole envelope line, calculate C, φ.

☆ Three-axis tester pressure chamber

The pressure chamber of the triaxial tester is the main core part of the test, which is composed of soil sample, soil sample base, soil sample cap, and wrapped in the soil sample outside

Latex film; The pressure outer shell is composed of high pressure resistant plexiglass cylinder, aluminum alloy base, top cover, pressure transmission piston, piston sleeve, and in the pressure chamber at the bottom of the pore pressure sensor, back pressure, air intake and drainage, pore pressure and other pipelines, as well as a variety of sensor cable fastener interfaces and valves.

☆ Confining pressure control device

Under normal circumstances, the confining pressure is controlled by hydraulic pressure, but due to the vibration of the confining pressure fluctuations, the device is currently controlled by air pressure. Air pressure control is provided by an inlet proportional valve to provide a stable air pressure source. Pressure range: 0~900Kpa This method is convenient to operate. If necessary, water can be added to the top drainage position in the pressure chamber, and then air pressure control.

☆ Back pressure body change and pore pressure measurement system

The application of back pressure is mainly to solve the problem of soil sample saturation, of course, there are many ways to solve the saturation: vacuum suction saturation, head saturation,

Reverse pressure saturation and other methods. For general clay permeability coefficient: Larger than N *10-7cm/s, the back pressure volumetric change system, that is, the hydraulic controller, can be used to compress the air bubbles in the soil and improve its saturation. However, in this system, we can apply back pressure to one end of the soil sample and let it drain water at the other end of the soil sample, so that the air bubbles in the soil sample can be eliminated under the action of circulating water and the volume change can be measured. The measurement of pore pressure is stored by the digital quantity of the pore pressure sensor or directly input into the computer.